The private tour of Lark Distillery in Tasmania begins with “a breakfast whisky”, a daily ritual of the distillery team. “We drink this whisky in the morning to set our palate,” Chris Thomson, Head Distiller at Lark explains as we start the visit, a dram in hand. “The only thing I like more than making whisky, is sharing whisky with friends”, he adds.

Lark Distillery, Tasmania

Standing at the working distillery in hi vis jackets amongst the mash tun, fermenters and spirit stills, breathing in the heady air of the Angels Share, you stop for a moment to appreciate. Lark Whisky is where it all began for Australian whisky. Bill Lark, dubbed as the godfather of Australian whisky and recent inductee into the Whisky Hall of Fame at the World Whisky Awards in London was successful in getting The Distillation Act of 1901 amended in 1992 to allow for smaller volume spirit production. Thanks to his efforts, the Australian whisky industry was born.

Peat Smoker

The whisky production process at Lark begins with 300 kilos of Tasmanian-grown barley malted at Joe White Maltings, the largest malt producer in Australia then delivered to be peat-smoked onsite. Almost all of Lark’s whisky is peat smoked, no matter how light. The smoker takes 50 kilos of malt per tray. The malt is wet and placed in trays which have a gas ring underneath and a plate above where the peat is placed. As the barley dries, it sucks in the peat phenols and the peat character comes through. Depending on how it is smoked, it can yield an Islay style of iodine or a light sweetness with peat smoke.

Grist Mill

The barley is then run through the grist mill. Rollers crush the grain before it is mixed manually using a paddle. The aim is to mix it without getting any lumps. The mixture is stirred in one direction so that the current carries it around. It’s arduous work, and not for one who spends most of her time behind a keyboard.

Gourmantic making whisky

The result is a watery porridge kept between 60 and 65 degrees. After regular stirring, the mixture sits for about an hour and a half where an enzyme reaction takes place and breaks the starch into sugar.

“We end up with a good brew or sugary porridge”, Chris Thomson explains. At the bottom of the mash tun is a Lauter screen which separates the solids from the liquid. This is then pumped out and run through a cooling system of jacketed pipes. The wort then runs into one of the 1200 litre fill fermenters or washbacks.

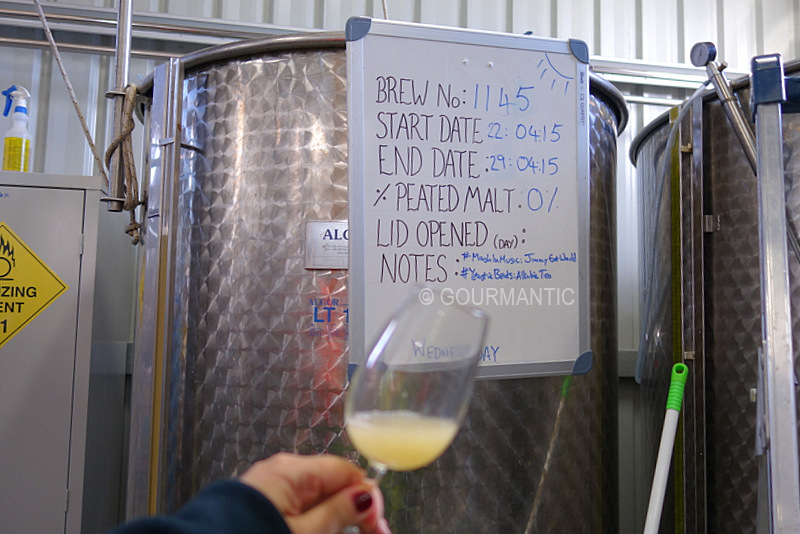

Tasting New Brews

The fermentation process is the point of difference for Lark. They have one of the longest fermentations in the world, lasting for seven days. Eight fermenters brew six days a week with double brewing now taking place twice a week.

Two types of yeast are pumped into the wort. Distillers yeast eats lots of sugar which creates a lot of alcohol. It also heats up and stresses the brewers yeast which is what gives some of the mid palate complexity and produces a lot of oils.

Fermenters

The yeasts create about 8-9% alcohol and at Lark, they prefer to keep it lower at 7.7-8%. They open the lids of the fermenters to allow in wild yeast and bacteria. With the build-up of Lactobacillus, the pH drops from around 5 to about 3.2 which increases ester production which gives candied orange peel and lemon peel notes. Yeast autolysis follows, breaking down dead yeast which gives the spirit butterscotch notes and the signature character of Lark whisky, the mouth feel.

Wash Still

The magnificent stills are to be admired. Made by stillmaker Peter Bailey from Tasmania, he is the man responsible for making stills at many distilleries including Sullivans Cove and Archie Rose. The wash still is made of 100% copper, a metal that strips out sulfur compounds. After each run, the still is cleaned for an hour using a pressure cleaner so as to remove high levels of sulfur from Lark’s long fermentation process.

Wash Still

1200 litres of spirit are placed in an 1800 litre still which results in a lot of fat molecules coming across. With extensive copper contact, there is a bigger surface area for the sulfides to be stripped.

The spirit goes up, condenses back down, reacts with the copper, eventually goes up the swan neck into the liner and the condenser and then runs out as low wines. The process runs for 11 hours, an hour per 100 litres which means more copper contact, more reflux, more gentle heating, resulting in more evenness across the palate.

Spirit Still

The spirit still has 600 litre capacity, a little baby as Chris calls it. The low wines go into the still and the falls and the feints are recycled though it. Everything is done by taste and nose. As it starts to come up, it boil off and to react with the copper then drips back down, comes up, drips back down, and again then it runs through shallow tube condenser. The first liquid that runs out are the falls, metallic in nature and not very pleasant. The process is repeated until the heart of the run is taken.

The heart of the run has a lot of citrus notes and florals. It dies off and becomes really flat. Then the middle of the palate starts to come through with a lot of malt flavours, a lot of grain flavours and then through the end, you get the feints and soapy sort of flavours. But the peat flavours also come through and it becomes all about balancing those flavours.

A Taste of Things to Come

When it comes to single casks, Lark is ever evolving, always trying to be better than the week before. “We have found that some of our whiskies are best at single casks”, Chris explains. With opportunities to experiment and do some marrying as well, we are offered a taste of a new whisky, the product of eight casks put together. Each barrel has been aged between five and seven and a half years. It’s delicious with a lot of oak and chewiness upfront and surprisingly not too aggressive at 64-65% ABV. “I feel this is only half done,” Chris adds.

Bottling Done by Hand

Lark’s unique flavour and character are attributed to the long fermentation process followed by the secondary fermentation, the breakdown of the dead yeast which creates waxiness and viscosity and in turn increases the surface tension. “The whisky holds itself together more so you don’t get that rush of alcohol driving out. We get a gentle fruitiness, with more warmth and more balance on the nose.”

Inside Bond Store

Over at the bond store, a row of 20 litre casks are named after songs: Hotel California, Money by Pink Floyd and so on. We taste Toto’s Africa, a bourbon cask from Makers Mark. “This is probably a scary 68 or 72%,” Chris explains. These are likely to be released around the end of the year. “They are all different and they are pressing the boundaries to a new level.”

When asked what is next for Lark, “I would like to do a heavily peated whisky to come out of Lark, maybe with a separate label. We could do something that is aligned with Islay and we could use Lark’s name or a different name. We are discussing that in the next few days. I think we can make it.”

Chris Thomson, Head Distiller

Lark Distillery runs tours (from $75 pp) which start at Lark’s Whisky Bar & Cellar Door in Hobart before travelling the distillery in Coal River Valley to look at each stage of the production. The tour concludes with tasting of Lark whiskies in the barrel warehouse before returning to the Cellar Door. The tour runs for approximately 2.5 to 3 hours. Book via email tours@larkdistillery.com.au or call (03) 62319088.

Gourmantic travelled to Tasmania as guests of Lark Distillery. With our heartfelt thanks to Chris Thomson for his time, for the tastings and for the good chat about the mutual love of spirits.

For more distilleries, visit the Australian Distillery Directory.

Photography © by Kevin Burke for Gourmantic – Copyright: All rights reserved.

[…] the night with an Australian Whisky and support our growing industry. Choose from Lark Whisky, Limeburners, Sullivans Cove, Nant, Hellyers Road Distillery and Overeem to name a […]

[…] Matured won first place followed by Limeburners Director’s Cut M96 in the second spot and Lark Whisky #395 Port Cask Matured in […]

[…] drams previously reviewed include Australian whiskies with Overeem, Lark Whisky, Sullivans Cove and Hellyers Road which drew a constant crowd. Also on taste was the Chivas Range, […]

[…] Top Shelf Boutique Drinks Festival held in Melbourne. Five champion trophies were presented with Lark Distillery taking out two […]

[…] lovers were in for a real treat at the Tasmania Pavilion, with Lark Whisky, Overeem, Sullivans Cove and newcomer to the show, Belgrove Rye […]

[…] such as Speyside & The Isles, Islay, Independent Bottlers and World Whiskies which include Lark Distillery, Sullivans Cove, Hellyers Road Distillery, Smiths and Starward as well as Hibiki and Hakushu […]

[…] peated Nikka Yoichi 15 YO. Taiwan is represented with Kavalan Whisky while Australia features Lark Port Cask, Starward and Sullivans Cove American […]

[…] we featured in our Top 10 Australian Craft Spirits from Mt Uncle Distillery in Cairns, Overeem and Lark Whisky from Tasmania, Crazy Uncle Moonshine from Perth, Sullivans Cove French Oak, Bakery Hill and […]

[…] with her father, Casey Overeem, while studying marketing at university in 2007. She is now Lark and Overeem Marketing Manager & Overeem Brand […]

[…] to Sydney the first micro distillery since the 1850s. Joe Dinsmoor is Head Distiller, an ex Lark Distillery alumni who started working there at the age of […]

[…] Lark Distillery is an Australian whisky producer located in Tasmania. They have been producing Single Malt whisky since 1992. […]

[…] years – drawing parallels with Australia’s own whisky godfather, Bill Lark of Tasmania’s Lark Distillery. Since 2008, 60 more distilleries opened in New York. He later lobbied for another change in law to […]

[…] Read more about Lark whisky in this Masterclass with Bill Lark and about Lark Distillery here. […]

[…] New Zealand Whisky Company 21 yo came third in the Single Malt category while Lark Distillery LD and Three Capes 10 yo took out second and third place in the Cask Strength […]

[…] include a few favourites such as Laphroaig, Lagavulin, Glenfiddich and the Balvenie. There’s even Lark Distillery single malt from Australia, Yamazaki and Nikka from Japan and Hudson single malt from the USA […]

[…] travelled to Tasmania as guests of Lark Distillery. With thanks to Bertie Cason of Sullivans Cove for his time during our […]

[…] next key factor is fermentation. Unlike Lark Distillery, Starward have a short fermentation period of 72 hours. Any longer and other flavours from […]

[…] and you’ll find Australian spirits such as Archie Rose Signature Gin, 666 Tasmanian Vodka, Lark Single Malt Whisky, Ord River Rum and Tromba […]

[…] Lark Distillery in Tasmania produces Forty Spotted Rare Tasmanian Gin (40% ABV), named after Tasmania’s rarest bird. Traditional botanicals are steeped in neutral cane spirit and include juniper berry, coriander and lemon peel as well as the rare Tasmanian pepperberry which is responsible for the characteristic spicy notes. A versatile gin for anything from a G&T, Martini, Gibson, Negroni or simply sipped neat. […]